Enjene e 'ngoe le e' ngoe e tukang ka hare e na le hlooho ea cylinder (cylinder head) - karolo ea bohlokoa eo, hammoho le hlooho ea piston, e etsang kamore e tukang, 'me e phetha karolo ea bohlokoa ts'ebetsong ea litsamaiso tsa motho ka mong tsa yuniti ea matla.Bala tsohle ka lihlooho tsa li-cylinder, mefuta ea tsona, moralo, ts'ebetso, tlhokomelo le tokiso sehloohong sena.

Hlooho ea silinda ke eng?

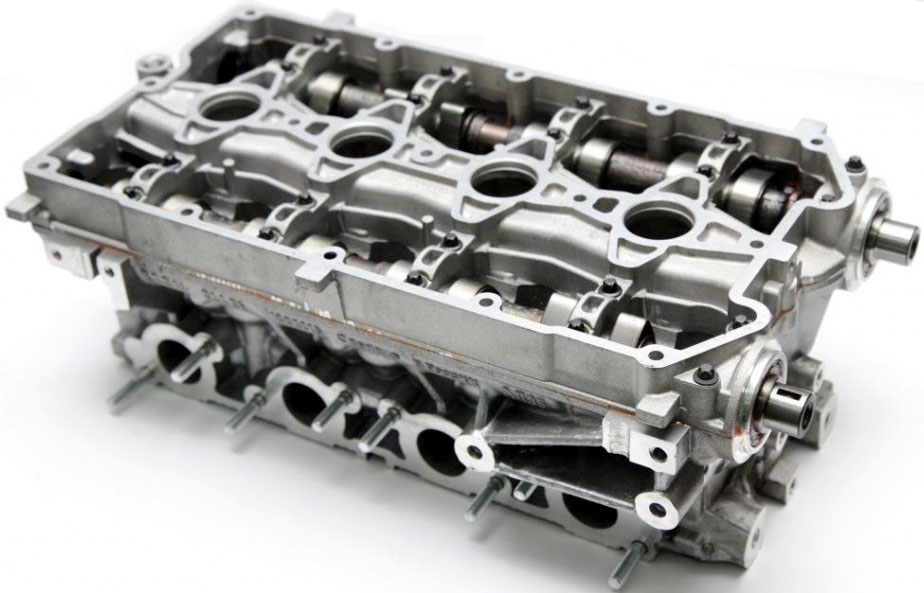

Hlooho ea cylinder (hlooho ea silinda) ke yuniti ea enjene e tukang e ka hare e kentsoeng kaholimo ho boloko ba silindara.

Hlooho ea silinda ke e 'ngoe ea likarolo tse ka sehloohong tsa enjene e tukang ka hare, e netefatsa ts'ebetso ea eona mme e khetholla litšobotsi tsa eona tse kholo tsa ts'ebetso.Empa hlooho e tšepetsoe mesebetsi e mengata:

• Ho thehoa ha likamore tse tukang - karolong e ka tlaase ea hlooho, e teng ka ho toba ka holim'a silinda, kamore e tukang e etsoa (ka mokhoa o itseng kapa ka ho feletseng), molumo oa eona o feletseng o thehoa ha piston ea TDC e fihla;

• Ho fana ka moea kapa motsoako oa mafura-moea ho kamoreng ea mollo - likanale tse lumellanang (ho kenngoa) li entsoe ka hlooho ea cylinder;

• Ho tlosoa ha likhase tsa ho qeta ho tloha likamoreng tse tukang - litsela tse lumellanang (ho qeta) li entsoe ka hlooho ea cylinder;

• Ho pholile ha motlakase oa motlakase - hloohong ea cylinder ho na le likanale tsa jekete ea metsi eo pholileng e potolohang ka eona;

• Ho netefatsa ts'ebetso ea mokhoa oa ho tsamaisa khase (nako) - li-valve li teng hloohong (ka likarolo tsohle tse amanang - li-bushings, litulo) tse bulang le ho koala mechine ea ho kenya le ea ho qeta ho latela liropo tsa enjene.Hape, nako eohle e ka ba hloohong - camshaft (shafts) e nang le li-bearings le likere, koloi ea valve, liliba tsa valve le likarolo tse ling tse amanang le tsona;

• Lubrication ea likarolo tsa nako - likanale le lijana li etsoa hloohong, eo ka eona oli e phallelang holim'a likarolo tsa ho phunya;

• Ho netefatsa ts'ebetso ea sistimi ea ente ea mafura (ka lienjineng tsa diesel le ente) le / kapa sistimi ea ho tima (ka lienjineng tsa peterole) - li-injection tsa peterole le / kapa li-spark plug tse nang le likarolo tse amanang (hammoho le li-plug tse khanyang tsa diesel) li kentsoe holim'a hlooho;

• Ho sebetsa e le setho sa 'mele bakeng sa ho kenya likarolo tse sa tšoaneng - li-manifolds tsa ho kenya le ho ntša metsi, li-sensor, liphaephe, li-brackets, li-rollers, likoahelo le tse ling.

Ka lebaka la mefuta e mengata ea mesebetsi, litlhoko tse thata li behoa hloohong ea silinda, 'me moralo oa eona o ka ba o rarahaneng haholo.Hape kajeno ho na le mefuta e mengata ea lihlooho tseo ho tsona ts'ebetso e hlalositsoeng e sebelisoang ka tsela e 'ngoe kapa e' ngoe.

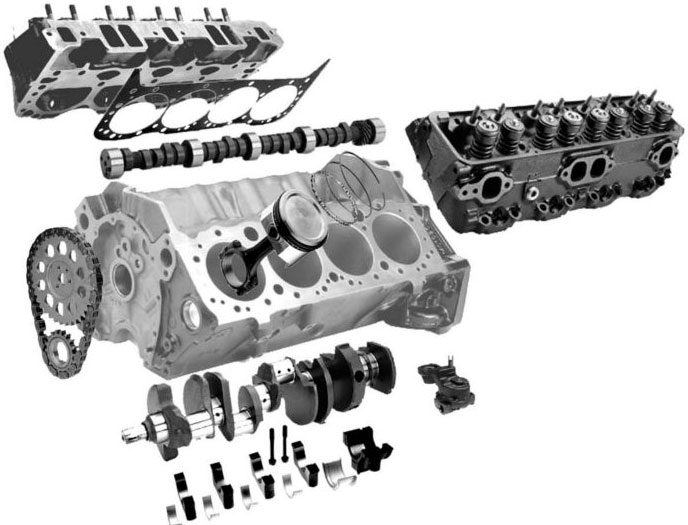

Mefuta ea lihlooho tsa li-cylinder

Lihlooho tsa li-cylinder li fapane ka moralo, mofuta le sebaka sa kamore ea mollo, boteng le mofuta oa nako, hammoho le morero le likarolo tse ling.

lihlooho tsa li-cylinder li ka ba le e 'ngoe ea meralo e mene:

• Hlooho e tloaelehileng bakeng sa li-cylinders tsohle tse ka har'a li-injini;

• Lihlooho tse tloaelehileng bakeng sa mola o le mong oa li-cylinders ka li-engines tse nang le sebōpeho sa V;

• Lihlooho tse arohaneng bakeng sa li-cylinders tse ngata tsa li-multi-cylinder in-line engines;

• Lihlooho tsa li-cylinder tsa motho ka mong ka har'a li-cylinder tse le 'ngoe, tse peli le tse ngata, tse nang le sebōpeho sa V le tse ling.

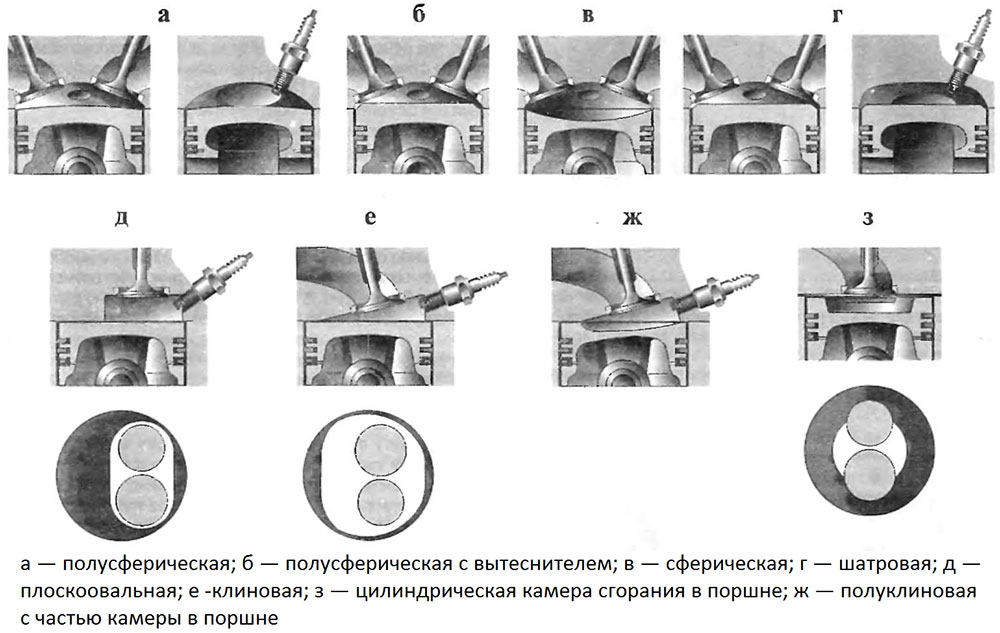

Mefuta e ka sehloohong ea likamore tse tukang tsa lienjineri tse tukang ka hare

Lienjineng tse tloaelehileng tsa 2-6-cylinder in-line, lihlooho tse tloaelehileng li sebelisoa hangata ho koahela li-cylinders tsohle.Lienjineng tse nang le sebopeho sa V, lihlooho tse peli tsa li-cylinder tse tloaelehileng moleng o le mong oa li-cylinders le lihlooho tsa motho ka mong bakeng sa silindara ka 'ngoe li sebelisoa (mohlala, lienjineri tse robeli tsa KAMAZ 740 li sebelisa lihlooho tse arohaneng bakeng sa moqomo o mong le o mong).Lihlooho tse arohaneng tsa li-cylinder tsa li-in-line li sebelisoa hangata haholo, hangata hlooho e le 'ngoe e koahela li-cylinders tse 2 kapa tse 3 (mohlala, ka li-cylinder tse tšeletseng tsa diesel MMZ D-260 lihlooho tse peli li kenngoa - e le' ngoe bakeng sa li-cylinders tse 3).Lihlooho tsa li-cylinder li sebelisoa lienjineng tse matla tsa diesel (mohlala, lienjineng tsa diesel tsa Altai A-01), hammoho le likarolo tsa matla tsa moralo o khethehileng (boxer two-cylinder, star, joalo-joalo).'Me ka tlhaho, ke lihlooho tsa motho ka mong feela tse ka sebelisoang lienjineng tse nang le silinda e le' ngoe, tse etsang mesebetsi ea radiator e pholileng moea.

Ho ea ka sebaka sa kamore ea mollo, ho na le mefuta e meraro ea lihlooho:

• Ka kamore e tukang hloohong ea cylinder - tabeng ena, ho sebelisoa piston e nang le tlaase e tlaase, kapa e nang le displacer;

• Ka kamore e tukang hloohong ea cylinder le piston - tabeng ena, karolo ea kamore e tukang e etsoa hloohong ea piston;

• Ka kamore e tukang ka piston - tabeng ena, karolo e ka tlaase ea hlooho ea silinda e bataletse (empa ho ka 'na ha e-ba le likheo tsa ho kenya li-valve sebakeng se sekametseng).

Ka nako e ts'oanang, likamore tse tukang li ka ba le libopeho le litlhophiso tse fapaneng: li-spherical and hemispherical, hipped, wedge le semi-wedge, flat-oval, cylindrical, complex (e kopantsoeng).

Ho latela boteng ba likarolo tsa nako, hlooho ea yuniti ke:

• Ntle le nako - lihlooho tsa li-multi-cylinder low-valve le single-cylinder tse peli tse se nang li-valve;

• Ka li-valve, matsoho a rocker le likarolo tse amanang le tsona - lihlooho tsa enjene tse nang le camshaft e tlaase, likarolo tsohle li teng ka holim'a hlooho ea cylinder;

• Ka nako e tletseng - camshaft, valve drive le li-valve tse nang le likarolo tse amanang, likarolo tsohle li teng karolong e ka holimo ea hlooho.

Qetellong, lihlooho li ka aroloa ho ea ka morero oa tsona ka mefuta e mengata - bakeng sa li-diesel, peterole le lisebelisoa tsa matla a khase, bakeng sa lienjini tse lebelo le tlaase le tse qobelloang, bakeng sa lienjini tse tukang tsa ka hare tse pholileng ka metsi le moea, joalo-joalo Maemong ana kaofela. , lihlooho tsa li-cylinder li na le likarolo tse itseng tsa moralo - litekanyo, ho ba teng ha li-channel tse pholileng kapa li-fin, sebōpeho sa likamore tse tukang, joalo-joalo Empa ka kakaretso, moralo oa lihlooho tsena kaofela o tšoana hantle.

moralo oa hlooho ea silinda

Karolo ea hlooho ea silinda

Ka mokhoa o hlophisitsoeng, hlooho ea silinda ke karolo e tiileng e entsoeng ka thepa e nang le mocheso o phahameng oa mocheso - kajeno hangata ho sebelisoa li-alloys tsa aluminium, tšepe e tšoeu ea tšepe le li-alloys tse ling.Likarolo tsohle tsa litsamaiso tse teng ho eona li thehiloe hloohong - liteishene tsa ho kenya le ho ntša metsi, masoba a li-valve (li-valve guide bushings li hatelloa ho tsona), likamore tse tukang, litulo tsa li-valve (li ka etsoa ka li-alloys tse thata), libaka tsa tšehetso bakeng sa ho hola. likarolo tsa nako, liliba le likoti tse kentsoeng bakeng sa ho kenya likerese le / kapa li-nozzles, liteishene tsa sistimi e pholileng, liteishene tsa sistimi ea lubrication, Haeba hlooho e etselitsoe enjene e nang le camshaft e holimo, ebe ho etsoa bethe ka holim'a eona e kaholimo bakeng sa ho beha shaft. (ka li-liner).

Likarolong tse ka lehlakoreng tsa hlooho ea cylinder, ho etsoa libaka tsa li-filler bakeng sa ho kenya letsoho le ho ntša metsi a mangata.Ho kenngoa ha likarolo tsena ho etsoa ka ho tiisa li-gaskets tse sa kenyelletseng ho tsoa ha moea le ho tsoa ha metsi.Lienjineng tsa morao-rao, ho kenngoa ha likarolo tsena le tse ling hloohong ho etsoa ka li-studs le linate.

Karolong e ka tlase ea hlooho ea cylinder, sebaka sa ho tlatsa se entsoe bakeng sa ho beoa holim'a block.Ho etsa bonnete ba ho tiea ha likamore tse tukang le likanale tsa sistimi e pholileng, gasket e teng pakeng tsa hlooho ea silinda le setsi sa khoebo.Ho tiisoa ho ka etsoa ka li-gaskets tse tloaelehileng tse entsoeng ka paronite, thepa e entsoeng ka rabara, joalo-joalo, empa lilemong tsa morao tjena, seo ho thoeng ke lipakete tsa tšepe li 'nile tsa sebelisoa ka ho eketsehileng - li-gaskets tse entsoeng ka koporo tse nang le lisebelisoa tsa maiketsetso.

Karolo e ka holimo ea hlooho e koetsoe ka sekwahelo (tšepe e entsoeng ka setempe kapa polasetiki) e nang le molala oa ho tlatsa oli le setopo.Ho kenngoa ha sekoahelo ho etsoa ka gasket.Sekoahelo se sireletsa likarolo tsa nako, li-valve le liliba ho tloha litšila le tšenyo, hape se thibela ho qhalana ha oli ha koloi e ntse e tsamaea.

Moqapi oa hlooho ea cylinder

Ho kenngoa ha hlooho ea cylinder ho thibela ho etsoa ka li-studs kapa bolts.Li-studs li ratoa haholo bakeng sa li-block tsa aluminium, kaha li fana ka clamp e ka tšeptjoang hloohong 'me ka ho lekana li aba meroalo 'meleng oa block.

Lihlooho tsa li-cylinder tsa lienjine tse pholileng moeeng (sethuthuthu, scooter le tse ling) li na le mapheo a ka ntle - ho ba teng ha mapheo ho eketsa haholo sebaka sa hlooho, ho netefatsa hore pholiso ea eona e atlehang ke ho phalla ha moea o tlang.

Litaba tsa tlhokomelo, tokiso le ho nchafatsa hlooho ea cylinder

Hlooho ea li-cylinder le likarolo tse behiloeng holim'a eona li tlas'a meroalo ea bohlokoa, e lebisang ho senyeha ha tsona ho matla le ho senyeha.Joalo ka molao, ho se sebetse hantle ha hlooho ka boeona ha se hangata - tsena ke li-deformations tse fapaneng, mapetsong, tšenyo ka lebaka la kutu, joalo-joalo. sebaka (ntle le diphetoho).

Hangata, ho senyeha ha hlooho ea li-cylinder ho etsahala lits'ebetsong tse kentsoeng ho eona - nako, lubrication, joalo-joalo Hangata sena ke ho roala ha litulo tsa li-valve le li-bushings, li-valve ka botsona, likarolo tsa koloi, camshaft, joalo-joalo Maemong ana kaofela, likarolo tse nang le bokooa li nkeloa sebaka. kapa e lokisitsoe.Leha ho le joalo, karacheng, mefuta e meng ea ho lokisoa e thata ho e etsa, ka mohlala, ho hatella le ho hatella li-valve guide bushings, litulo tsa li-valve le mosebetsi o mong o ka khoneha feela ka sesebelisoa se khethehileng.

Tlhokomelo e khethehileng e lokela ho lefshoa ho kenngoa ka nepo ha hlooho ea silinda.Ke habohlokoa ho hopola hore cylinder head gasket e lahloa, e tlameha ho fetoloa haeba hlooho e qhaqhoa, ho kenngoa hape ha karolo ena ha ho amohelehe.Ha u kenya hlooho ea cylinder, taelo e nepahetseng ea ho tiisa li-fasteners (li-studs kapa bolts) e lokela ho hlokomeloa: hangata mosebetsi o qala ho tloha bohareng ba hlooho ka ho sisinyeha ho ea ka thōko.Ka ho tiisa hona, mojaro o hloohong o ajoa ka mokhoa o ts'oanang 'me li-deformation tse sa amoheleheng li thibeloa.

Nakong ea ts'ebetso ea koloi, tlhokomelo ea hlooho le litsamaiso tse teng ho eona li lokela ho etsoa ho latela litaelo le likhothaletso tsa moetsi.Ka tlhokomelo le ho lokisoa ka nako, hlooho ea cylinder le enjene eohle li tla sebetsa ka botšepehi le ka katleho.

Nako ea poso: Aug-21-2023